A team led by Cornell has achieved the holy grail of sustainable tech: They created an affordable way to generate 'green' hydrogen without carbon using sunlight-driven electrolysis of saltwater. As an added bonus, this process also yields drinking water.

The team's combined solar still-electrolyzer (SDE) apparatus, reported in Energy & Environmental Science Currently, this system generates 200 milliliters of hydrogen per hour at an energy efficiency of 12.6%, extracting hydrogen directly from seawater using only natural sunlight. Researchers predict that over the next fifteen years, this technology might lower the price of producing green hydrogen to as little as $1 per kilogram—crucial for reaching zero carbon emissions by 2050.

"WATER and energy are essential for daily living; however, generally speaking, increasing energy production often requires greater water consumption," explained Lenan Zhang, an assistant professor at the Sibley School of Mechanical and Aerospace Engineering within Cornell Engineering, who headed the initiative.

Conversely, access to potable water is essential since more than half of the world’s population experiences water shortages. Consequently, this creates a constraint in the production of green hydrogen, which also impacts the associated costs.

Green hydrogen is generated by breaking down "ultra pure" — such as deionized — water molecules into hydrogen and oxygen via electrolysis. This method incurs significant costs due to the substantial quantity of purified water needed for the process; consequently, the expense of producing green hydrogen may be approximately tenfold compared to conventional hydrogen production.

That’s why we developed this technology," Zhang stated. "We considered, ‘What is the most plentiful resource on our planet?’ Both solar power and seawater are essentially inexhaustible and available without cost.

As a researcher at MIT, Zhang started investigating methods to utilize solar energy for converting seawater into drinking water via thermal desalination—a project recognized by Time magazine as one of the year’s top "Innovations of 2023." Upon joining Cornell University in 2024, he secured funding from the National Science Foundation to further develop this technology with an aim toward producing clean hydrogen.

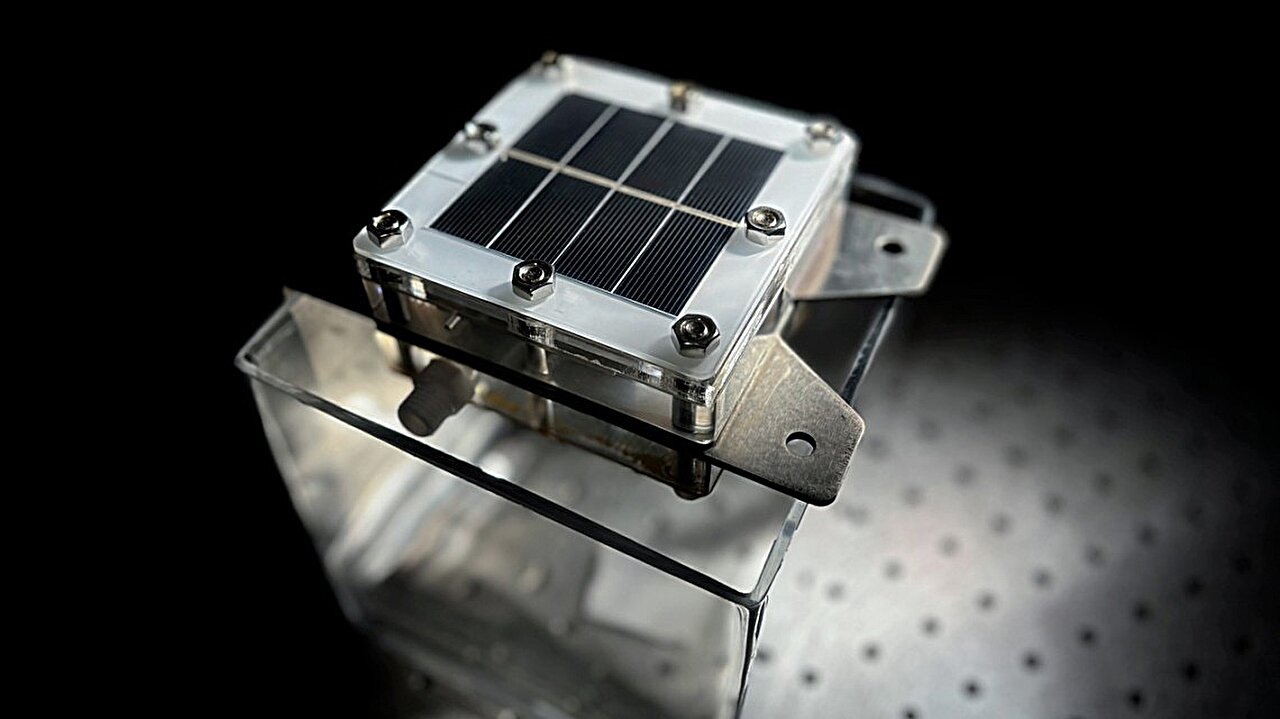

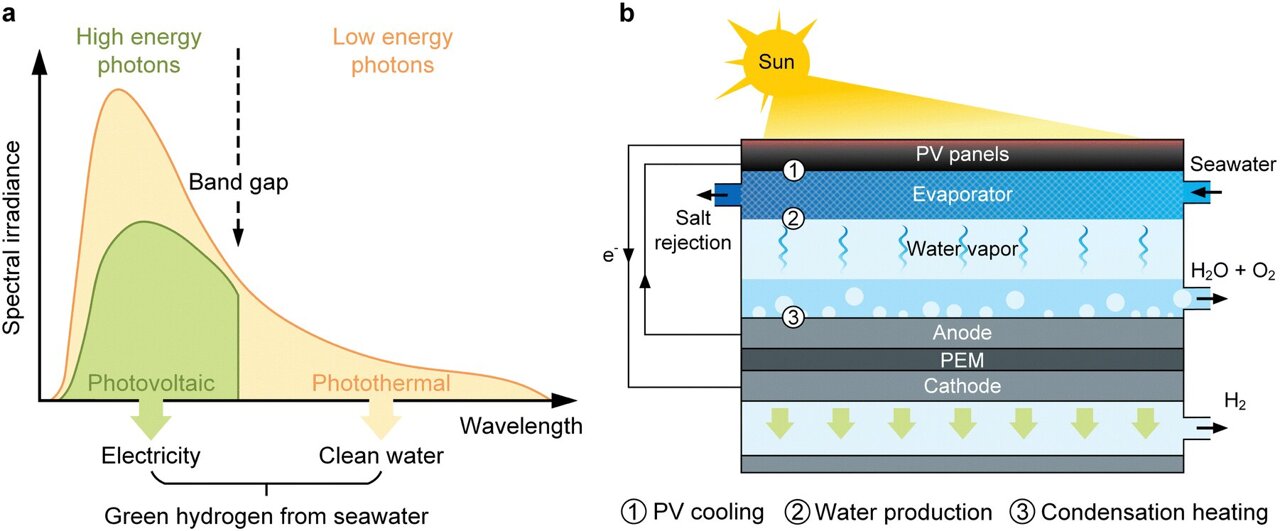

Collaborating with researchers from MIT, Johns Hopkins University, and Michigan State University, Zhang’s team created a prototype measuring 10 cm by 10 cm. This device takes advantage of one of the limitations of photovoltaic technology—its lower conversion efficiency. Typically, PV cells manage to transform around 30% of sunlight into electrical power, releasing the remainder as excess heat. However, this group’s invention captures much of this discarded heat, using it to raise the temperature of seawater until it vaporizes.

The shorter wavelengths of sunlight interact with the solar cells to produce electricity, while the longer wavelengths create waste heat that powers seawater desalination," Zhang explained. "In this manner, every bit of solar energy gets utilized efficiently; nothing goes to waste.

For interfacial thermal evaporation to take place, an essential element known as a capillary wick is required. It captures the water and forms a thin layer directly touching the solar panel. By doing so, just this slim film requires heating instead of a substantial amount of water, which amplifies the evaporation efficiency to over 90%.

After the seawater evaporates, the salt remains, and the purified steam transforms back into fresh water. This water then goes through an electrolyzer that separates the water molecules into hydrogen and oxygen.

"This is an intricately interconnected system. Designing this posed significant challenges due to extensive interdependencies: desalination linked with electrolysis, electrolysis connected to the solar panels, and the solar panels tied back to desalination via processes involving solar, electric, chemical, and thermal energy conversions and transfers," Zhang explained.

For the first time, we can generate enough water to meet both the needs for hydrogen production and have surplus available for drinking purposes. Killing two birds with one stone.

The present expense for producing green hydrogen stands at around $10 per kilogram, as stated by Zhang. However, considering abundant sunlight and seawater resources, within a span of 15 years, his team’s apparatus has the potential to reduce this cost to just $1 per kilogram. Additionally, Zhang envisions integrating this technology with solar farms to assist in cooling photovoltaic panels. This integration could enhance their effectiveness and extend their operational life.

“We aim to minimize carbon emissions and prevent pollution. At the same time, we prioritize costs since reduced expenses could lead to greater market opportunities for widespread use,” he stated. “We see significant potential for extensive future deployments.”

More information: Xuanjie Wang and colleagues achieved over 12% efficiency in solar-driven green hydrogen generation using seawater. Energy & Environmental Science (2025). DOI: 10.1039/D4EE06203E

Provided by Cornell University

This tale was initially released on Tech Xplore . Subscribe to our newsletter For the most recent updates on science and technology news.